Hva er MPX180 Quantitative Biased Belt Lærslipemaskin?

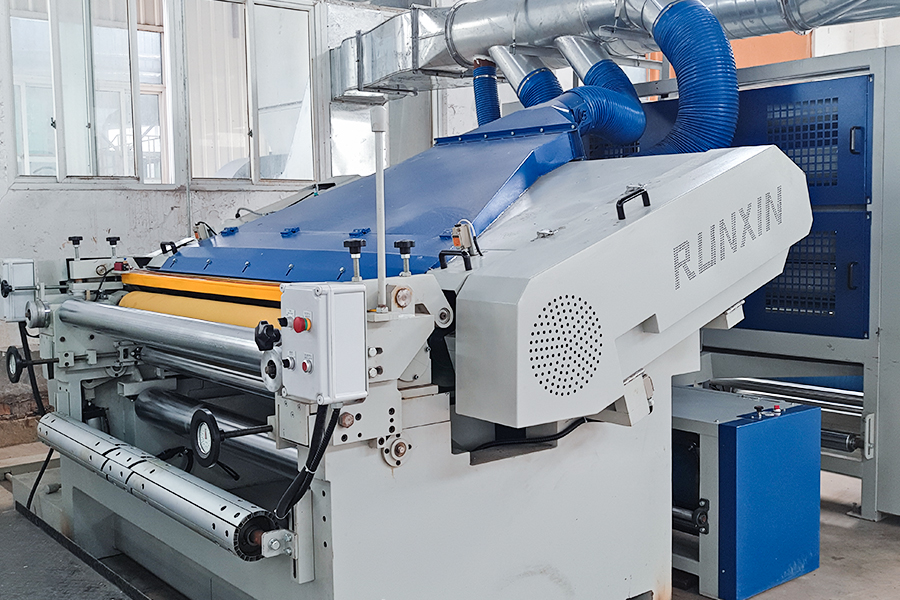

Den MPX180 kvantitativ forspent belteskinnslipemaskin er en svært integrert, helautomatisk lærslipemaskin som kombinerer allsidighet, høypresisjonskontroll, enkelt vedlikehold og bred kompatibilitet for å møte de ulike behovene til den moderne lær- og komposittmaterialeprosesseringsindustrien. Dens kjernedesign ligger i det avanserte 3200 mm sirkulære slipebåndet og skråbåndslipemekanismen, en innovativ design som gir betydelige ytelsesfordeler.

Den 3200mm circular sanding belt provides a longer contact area for sanding, eliminating the transverse defects caused by sanding belt seams in traditional sanding machines, thereby ensuring a smooth and uniform surface finish on the processed fabric. This circular sanding belt design reduces machine downtime, making belt changes quick and easy, significantly improving production efficiency.

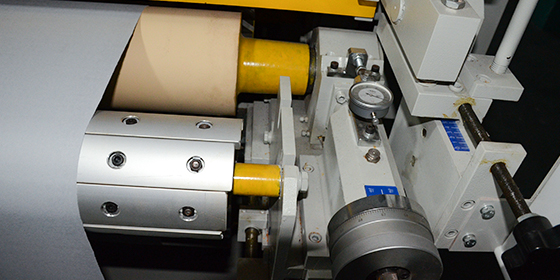

Den beveled belt grinding mechanism effectively improves sanding uniformity and accuracy by adjusting the angle of contact between the sanding belt and the material. The operator can flexibly adjust the angle, pressure, and sanding belt speed to achieve precise surface treatments for different leather materials, such as cowhide, sheepskin, microfiber leather, and synthetic composites. This precise control ensures that the finished leather meets high visual and tactile standards, meeting the stringent requirements of the high-end footwear, automotive interior, and furniture industries.

Den MPX180 Quantitative Biased Belt Leather Grinding Machine is more than just a simple flat grinder. It supports a variety of processing modes, including standard flat grinding, pattern grinding, and complex edge and corner trimming. Pattern grinding allows for customized textures on the leather surface, enhancing the product's design and added value. Edge and corner trimming ensures dimensional accuracy during cutting and splicing, minimizing waste.

Den machine is highly automated and equipped with an intelligent CNC system, allowing operators to easily set and change parameters, meeting the needs of small-batch, diversified production. Its modular design also makes routine maintenance and parts replacement quick and efficient, significantly reducing the risk of production downtime.

Hvordan bruke MPX180 Quantitative Biased Belt Lærslipemaskin?

Den MPX180 Quantitative Biased Belt Leather Grinding Machine's intuitive and convenient operation makes it particularly suitable for deployment in automated production lines for medium- to large-scale leather goods factories. The following are detailed operating steps:

Materiallasting: Den operator must lay the material to be processed (such as microfiber leather, PU, PVC, non-woven fabrics, synthetic fibers, or cotton) neatly and flatly on the conveyor platform, ensuring that the edges of the material are aligned to ensure stable conveyor belt feeding into the grinding area. The platform features an automatic adjustment function to accommodate materials of varying thicknesses and sizes, improving loading efficiency and reducing manual intervention.

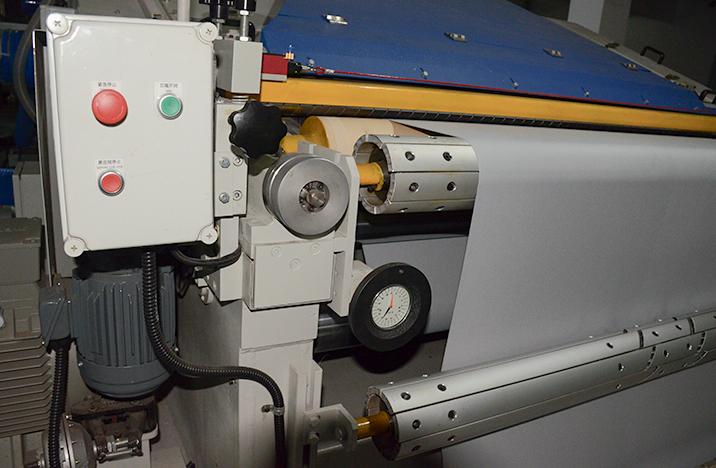

Funksjonsvalg: Den equipped intelligent CNC panel allows users to switch between desired processing modes, such as "Flat Grinding," "Fine Grinding," or "Cutting," with a single click. The system features a graphical interface for intuitive operation and a memory function for quick recall of commonly used parameter settings, reducing commissioning time and improving equipment utilization.

Parameterinnstilling: Basert på de fysiske egenskapene og prosesseringskravene til forskjellige materialer, kan operatøren stille inn nøkkelparametere som slipetrykk, båndhastighet og skråvinkel i CNC-systemet nøyaktig. MPX180 inkluderer et innebygd parameteranbefalingsbibliotek og støtter tilpassede innstillinger for å sikre optimale sliperesultater og materialbeskyttelse for en rekke stoffer.

Bytte av belte: Denne maskinen bruker et høystyrke, 3200 mm endeløst slipebånd med bare ett ledd, noe som reduserer risikoen for horisontale striper betydelig. Bytting av beltet krever ingen komplisert demontering; bare løsne strammemekanismen for enkelt å installere og plassere det nye beltet. Denne brukervennlige designen reduserer nedetid og forbedrer effektivt maskinens drift.

Starte slipeprosessen: Etter å ha bekreftet at materiallasting og parameterinnstillinger er riktige, kan maskinen startes. Under drift utfører MPX180 automatisk de konfigurerte trinnene og aktiverer samtidig fem høytrykksdyser, tre børster og et støvfjerningssystem med undertrykk for å fjerne støv og rusk som genereres under slipeprosessen, og holde slipebåndet rent og forbedre slipeeffektiviteten og kvalitetskonsistensen.

Utgang av ferdig produkt: Etter at behandlingen er fullført, transporterer systemet automatisk det behandlede materialet til utløpsporten. Det ferdige produktet har en jevn, flat overflate, fri for merkbare horisontale striper eller brennmerker, og tilbyr utmerkede visuelle og taktile egenskaper. Den kan behandles direkte for påfølgende trinn (som preging, belegg eller sying), noe som forbedrer den totale produksjonshastigheten og utbyttehastigheten betydelig.

Hva er kjernefordelene med MPX180 Quantitative Biased Belt Leather sliping Machine?

Multifunksjonell integrasjon, eliminerer problemet med kjedelige maskinbytte

Den MPX180 Quantitative Biased Belt Leather Grinding Machine integrates three core functions: cutting, flat grinding, and pattern grinding, truly achieving "one machine for multiple uses." Traditional production lines frequently require switching between machines to meet different processing requirements, which not only wastes time but also easily leads to docking errors, compromising overall product consistency. The MPX180, with its modular control system, can switch between functional modes in seconds to accommodate various leather processing steps. Whether coarse grinding or fine graining, the same machine can be used for both, significantly simplifying the operational process, reducing labor reliance, and improving workshop automation. This is crucial for leather processing plants striving for efficient and stable production capacity.

Innovativ slipebåndstruktur som eliminerer horisontale korndefekter

Den conventional abrasive belts used in traditional leather grinding equipment often have excessive or uneven seams, leaving noticeable horizontal grain defects on the leather surface, seriously affecting the finished product's appearance. The MPX180 Quantitative Biased Belt Leather Grinding Machine's design breaks with industry convention, featuring a 3200mm endless sanding belt with only one joint. Its angled grinding path effectively breaks the right angle between the belt joint and the direction of leather movement, significantly reducing the formation of horizontal streaks. This structure, combined with a high-precision belt tensioning system and a stable feed control mechanism, ensures a more uniform and continuous grinding process, ultimately resulting in a naturally smooth, flawless leather surface that meets the stringent aesthetic demands of the high-end market.

Intelligent støvfjerningssystem sikrer kontinuerlig og stabil produksjon

For å løse problemer som tilstopping av bånd og redusert slipeeffektivitet under kontinuerlig drift, er MPX180 utstyrt med et svært effektivt intelligent støvfjerningssystem. Dette systemet inkluderer fem høytrykksluftdyser og tre sett med dynamiske børster, som kontinuerlig fjerner fremmedlegemer og støv under hver slipesyklus. Videre fjerner et integrert støvfjerningssystem med undertrykk fine partikler i sanntid, og forhindrer at de samler seg i maskinen. Dette systemet forlenger ikke bare levetiden til slipebåndet effektivt, men sikrer også optimal rengjøring ved hver slipekontakt, noe som resulterer i mer konsistent og langvarig høykvalitetseffekt, redusert vedlikeholdsfrekvens og forbedret generell utstyrstilgjengelighet.

Sterk materialkompatibilitet tilpasser seg ulike markedskrav

Den MPX180 Quantitative Biased Belt Leather Grinding Machine boasts exceptional material adaptability, being compatible with a wide range of substrates, including microfiber leather, PU leather, PVC, artificial leather, non-woven fabrics, chemical fibers, and cotton, demonstrating exceptional process flexibility in practical applications. Different materials have varying requirements for parameters such as grinding accuracy, pressure, and speed. The MPX180's intelligent CNC adjustment system enables fine-tuning of multiple parameters, including grinding angle, feed speed, and pressure intensity, ensuring optimal grinding results without damaging the material. This feature enables the MPX180 to be widely used in a variety of market segments with demanding leather surface treatment standards, such as high-end footwear, fashion luggage, furniture leather, and automotive interiors, helping customers enhance their product competitiveness.